Chemical packaging

Products

in the chemical industry are used in almost all segments of the economy and

they cover many important segments of life in general merchandise. Therefore,

the quality of chemical products is essential for market acquisition, and

packaging used for the packaging and delivery of the product to the customer

plays an important role in ensuring a high-quality product. The role of

packaging in the chemical industry is to protect the product, ensure good

storage and transport conditions, attract customers and be suitable for use.

Our metal packaging (tin cans and buckets) for the chemical industry are

suitable for:

- paints, varnishes and adhesives industry

- petrochemical industry

- toothpaste, soap and grease industry

- pesticides industry

At the customer’s request, we can manufacture metal packaging for other purposes in various branches of the chemical industry.

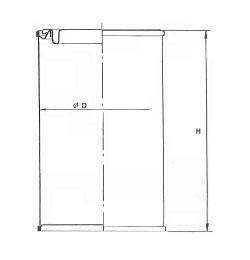

Three-piece tin can intended for use in chemical industry

| Diameter D [mm] |

Height of tin can H [mm] |

Volume V [ml] |

Note |

| 73 | 40-200 | 100-700 | BOTTOM WITH PL. CAP, INSERTED TOP LID, FLIP TOP LID, INSERTED TOP LID WITH RING |

| 83 | 40-200 | 150-950 | BOTTOM WITH PL. CAP |

| 84 | 40-210 | 160-1000 | BOTTOM WITH PL. CAP |

| 99 | 40-260 | 150-1700 | BOTTOM WITH PL. CAP, INSERTED TOP LID, FLIP TOP LID, INSERTED TOP LID WITH RING |

| 108 | 40-300 | 275-2400 | BOTTOM WITH PL. CAP |

| 130 | 50-260 | 500-3000 | FLIP TOP LID |

| 140 | 50-280 | 600-3750 | BOTTOM WITH PL. CAP |

| 163 | 50-400 | 625-7000 | BOTTOM WITH PL. CAP, WIRE HANDLE ON THE LID, INSERTED TOP LID WITH RING |

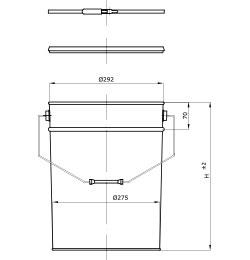

Drums ø292 / ø275 x

Steel conical drums, type 0A2, with detachable star or patent lid and single rib.

Steel conical drums, type 0A2, with detachable star or patent lid and single rib.

APPLICATION:

Nominal dimensions of the drum [mm] Height [mm] Nominal volume [L]

| Nominal dimensions of the drum [mm] | Height [mm] | Nominal volume [L] |

| ø292 / ø275 x "H" | 230 | 10 |

| 298 | 15 | |

| 346 | 18 | |

| 356 | 20 | |

| 386 | 23 |

SURFACE TREATMENT:

- Internal:

- a) Unprotected and clean

- b) Protective varnish

- External:

- a) Unpainted

- b) White lacquered

- c) Lithographed – as per customer demand

SEAMS:

- Side walls seam: longitudinal, flipped, electricity resistant welded seam

- Side wall-bottom seam: round, circular seam sealed with liquid rubber

LABELS:

a) Embossed approval label RID/ADR on the bottom

b) Embossed label of used metal sheets on the bottom